Giant reed (Arundo donax L.) is an herbaceous perennial plant belonging to the C3 group, but showing an unusual high photosynthetic capacity which enables the species to exploit efficiently the soil resources [1]. Recently, this crop gained very much interest in the bioenergy sector for both direct combustion, bioethanol and biogas production.

The harvesting period of the crop are linked to the final destination of the product. For instance, in Italy, in case of combustion, it is advisable to harvest the product early spring (February-March), when the plants have completed the lignifications process (higher heating value), and presents lower moisture and sugar content. On the other hand, if the final destination of the product is the production of bioethanol or biogas, the harvest may be carried out in different periods, when the plants are still in vegetation. In this case the product will have higher moisture and sugar levels. However, in all cases, it is necessary to schedule a storage period of variable length, which will be in function of the end use. The storage represent an important phase of the energy chain since during this period several characteristic of the crop can be lost, determining energy losses of high relevance.

Specific works on Arundo biomass storage are still limited. These mainly focus on open air storage in piles or windrows . Aim of the study was to test alternative storage systems of chopped Arundo by comparing the common storage in piles with innovative solutions such as the use of plastic containers (bins), supplied or not with forced air conditioning. Each storage configurations were analyzed in order to see how these systems affect the quality characteristics of the final product.

A five years old cultivation of common reed has been harvested in June 2013 at the experimental farm “Cà Rossa” (Anzola dell’Emilia, Italy) owned by the Research centre for Industrial Crops of the Agriculture Research Council (CRA-CIN).

Immediately after harvest, the biomass was transported to the Engineering unit of the Agriculture Research Council (CRA-ING, Moterotondo, Rome) where the storage trial was set up.

Three types of storage methods have been tested and replicated three times:

Three types of storage methods have been tested and replicated three times:

- open-air piles

- plastic bins

- plastic bins with forced aeration

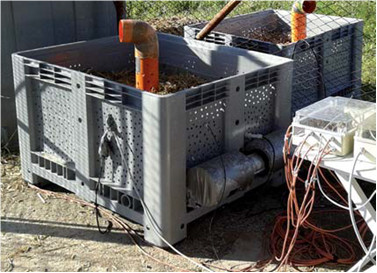

The bins utilized for storage had standard dimensions (100 cm length, 110 cm width, 55 cm height). Each bin was internally equipped with two probes model “pt 100” for the constant monitoring of heat development. These were located respectively at 15 and 30 cm of height from the bottom of the bins.

Each bin was filled with about 100 kg of chopped Arundo and perforated to allow air circulation. The forced aeration system installed in ventilated bins ensured an airflow of 1500 m3 h-1 at intervals of 20 minutes. The intermittence was adopted in order to avoid overheating of the electrical engines. The open-air piles were built using a similar quantity of biomass and maintaining as much as possible the layout of the other treatments. These were placed onto a plastic platform in order to avoid direct contact with soil and to uniform the support surface for all treatments. The platforms were in turn placed onto a wood pallet in order to simplify the handling operations. The monitoring of internal temperature was carried out using the same modalities of the bins.

At harvesting time, the evaluation of the biomass moisture content was calculated on four samples of 500 g appositely taken from fresh material. These were sealed in plastic bags to avoid moisture losses during transport to the laboratory. Then, the samples have been oven-dried at a temperature of 105°C for 24 hours in order to reach a constant weight.

At harvesting time, the evaluation of the biomass moisture content was calculated on four samples of 500 g appositely taken from fresh material. These were sealed in plastic bags to avoid moisture losses during transport to the laboratory. Then, the samples have been oven-dried at a temperature of 105°C for 24 hours in order to reach a constant weight.

Weekly, three samples of 500 g each were drawn randomly, at different height, from each treatment in order to determine the moisture content of the material in laboratory.

In order to evaluate the dry matter losses occurred in each treatment during storage, all bins were weighed at the beginning and respectively after 10, 15, and 30 days of storage using a scale. The data obtained from each measurement were then reported in dry weight basis by excluding the moisture content of the material. During the entire storage period, the climatic conditions such as temperatures (average, minimal and maximal), relative air humidity, and precipitations were monitored using a weather cab SIAP-MICROS DA9000” certified by SIAN (National Informative System for Agriculture).

Temperatures during storage

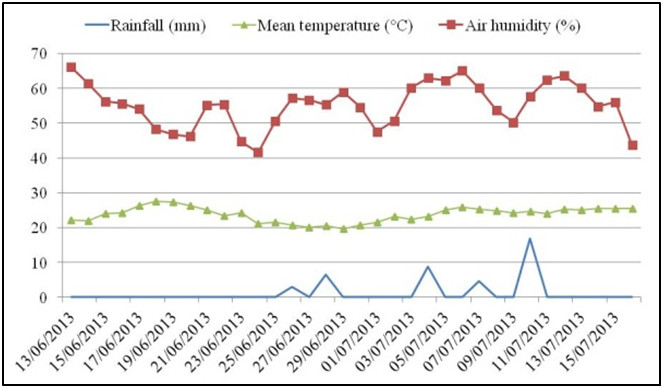

In order to evaluate the behavior of a product harvested in summer, the storage period started in the middle of June and ended in the middle of July. The mean temperatures ranged between 20 and 30°C, while relative air humidity was between 41 and 66%. The precipitations were limited to five events (see figure).

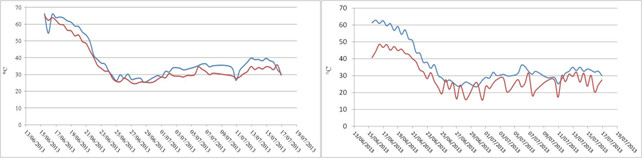

The conditioning of biomass by means of forced aeration was aimed at to favor the lowering of the moisture content in order to hamper the triggering of harmful microbial degradations. The temperatures at the end of the cycle reached 30°C in both outer heaps and bins without ventilation, while in those with engines it was leveled off at slightly lower levels (see figure below). The most noticeable difference in the conditioned bin concerned the trend of temperatures during the first 10 days since, on average, the values have always fluctuated between 10 and 30°C, while in the other two systems, the temperatures started from a level around 60°C and took about 10 days to stabilize.

The conditioning of biomass by means of forced aeration was aimed at to favor the lowering of the moisture content in order to hamper the triggering of harmful microbial degradations. The temperatures at the end of the cycle reached 30°C in both outer heaps and bins without ventilation, while in those with engines it was leveled off at slightly lower levels (see figure below). The most noticeable difference in the conditioned bin concerned the trend of temperatures during the first 10 days since, on average, the values have always fluctuated between 10 and 30°C, while in the other two systems, the temperatures started from a level around 60°C and took about 10 days to stabilize.

Such conditions have probably influenced the chemical and microbial processes, established soon after the beginning of storage, thus influencing the features of the final product. Unlike other treatments, the temperatures inside the ventilated bins never reached high levels, with peaks just above 30°C. This suggests that the instantaneous evaporation of water due to ventilation lowered in short time the water content to values that do not meet the needs of micro-organisms, thus inhibiting the potential fermentation of biomass. On the other hand, in the outdoors heaps and in unventilated bins the evolution of inner temperature was almost analogous, with a sharp rise of values around 60°C in the first hours followed by a leveling to those of the outside environment during the next days. In these cases it can be speculated that, since the beginning of the storage operations, an intense fermentation activity established inside the biomass.

Moisture content and dry matter

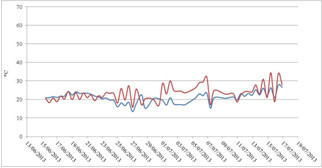

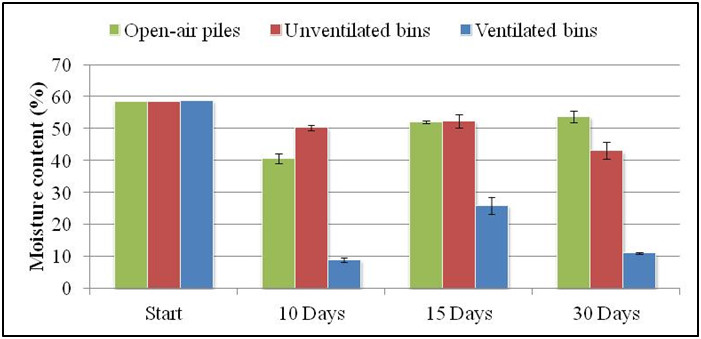

At harvesting time, the average moisture content of the chopped biomass was about 59%. After 10 days of storage, in ventilated bins it decreased of about 50%, remaining between 8 and 26% for the entire storage period. On the contrary, in unventilated bins and open-air piles, the average moisture content decreased respectively of 8 and 16% after 10 days, remaining between 43 and 53% for the entire storage period.

At harvesting time, the average moisture content of the chopped biomass was about 59%. After 10 days of storage, in ventilated bins it decreased of about 50%, remaining between 8 and 26% for the entire storage period. On the contrary, in unventilated bins and open-air piles, the average moisture content decreased respectively of 8 and 16% after 10 days, remaining between 43 and 53% for the entire storage period.

The increase in moisture content observed after 15 days of storage was probably due to the precipitation events occurred before sampling the biomass. With the ideal conditions restored in the following 15 days, the presence of the ventilation has allowed to smoothly return to the moisture levels observed on the tenth day, while in the unventilated bins the decreasing was rather gradual (with a final value four-fold greater than the ventilated bins) and in the open piles, more prone to the environmental conditions, no further reductions occurred, but actually the moisture content slightly increased.

The rapid lowering of the moisture content was positively reflected on the dry matter loss. The latter was, in fact, remarkably restrained in the conditioned bins, since after one month the losses amounted to 14.28%. The difference with the other treatments, where the final values were 42.2% and 43.6% (respectively for the non ventilated bins and the outdoor piles) proved to be therefore considerable.

Conclusion

The final quality of the chopped Arundo harvested from plants in full vegetation can be significantly influenced from storage system. The use of the forced aeration system had the purpose to rapidly reduce the moisture content in order to hinder the microbial degradation processes and reduce as much as possible the losses during storage. The results have highlighted that the application of a conditioning system allowed to obtain dry material reducing dramatically the dry matter losses that occur in traditional storage with ligno-cellulosic biomass (open-air heaps). From this point of view, the relationship binding the moisture content of the biomass and the processing is fairly well defined, since the thermal conversion requires materials with a low moisture content (below 50% ), while the bio-conversion can use materials with high relative humidity, provided that the highest possible percentage of raw fiber is conserved. Consequently, on the basis of the results obtained, the use of a storage system with forced ventilation seems suitable when a highly dehydrated biomass with the greatest amount of dry matter is required. However, considering the values of dry matter losses, in order to meet the supply needs of biogas/bioethanol plants, it must be assessed the option of multiple harvesting during the year or the ensilage of the product.