There has been renewed interest in biomass energy since the min-1990s because of the quest for mitigating global climate change. In particular biofuels is currently driving the interest in bioenergy sector. Also nowadays, the profits obtainable from the use of biomass as renewable energy source have determined a significant increase of the investments made in this sector In this regard, the mechanization plays an important role involving operations such as planting and harvesting at every scale. Studies and researches are designed to address properly the farmers in making appropriate business decisions to maximize profits. Panacea group is committed to the development of the agro-energy chain by identifying the most promising mechanical solutions suitable for different contexts. The following work provides a summary of the main energy crops and the a cost analysis of the different transportation systems used to collect and delivery the product to the processing plants.

Biomass for energy use can be carried in two different forms:

- wood chip;

- bales.

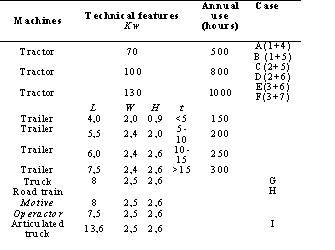

In order to evaluate the costs of the supply chain it is necessary to consider the form of biomass, transportation systems and type of yard for harvesting. In this work are overall considered different types of transportation which are displayed in table I.

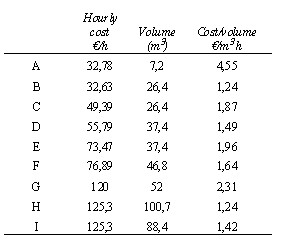

The most important parameters to be considered for evaluating transportation costs are the carrying capacity, the traveling time, and the hourly cost of the transport means used. The total hourly cost of the machines has been calculated taking into account technical and economic parameters such as the purchase price, the residual value, the estimated useful life, the interest on capital invested, and the maintenance costs. During the study of CRA were considered the hours of use reported by farms; the prices and sizes were obtained from journals "Trattori, trincia, mietitrebbie” periodically published in Italy (table II). The total hourly cost of road transport systems has been calculated considering the information of the article 7sexies (February, 2009 n° 5) relating to fuel cost per kilometer. The final cost for transporting biomass was evaluated hypothesizing two distances (20 and 70 km), and assuming a speed of 40 km/h for tractors and 70 km/h for road transport.

The most important parameters to be considered for evaluating transportation costs are the carrying capacity, the traveling time, and the hourly cost of the transport means used. The total hourly cost of the machines has been calculated taking into account technical and economic parameters such as the purchase price, the residual value, the estimated useful life, the interest on capital invested, and the maintenance costs. During the study of CRA were considered the hours of use reported by farms; the prices and sizes were obtained from journals "Trattori, trincia, mietitrebbie” periodically published in Italy (table II). The total hourly cost of road transport systems has been calculated considering the information of the article 7sexies (February, 2009 n° 5) relating to fuel cost per kilometer. The final cost for transporting biomass was evaluated hypothesizing two distances (20 and 70 km), and assuming a speed of 40 km/h for tractors and 70 km/h for road transport.

A preliminary outcome indicates that the cost per unit of volume transported is directly linked to the volume of load. For this reason, the reduced hourly cost and the high load capacity would determine the reduction of costs. Considering agricultural equipment, the outcome of the survey evidenced how the most advantageous solution was the tractor of average power combined to a trailer having 26,4 m3 of average carrying capacity. In this case, the relationship between the hourly cost and the carrying capacity is 1,24 €/m3h. The following step, the transport to the bio-refinery, showed how the road train is the more economical solution with a cost of 1,24 €/m3h.

A preliminary outcome indicates that the cost per unit of volume transported is directly linked to the volume of load. For this reason, the reduced hourly cost and the high load capacity would determine the reduction of costs. Considering agricultural equipment, the outcome of the survey evidenced how the most advantageous solution was the tractor of average power combined to a trailer having 26,4 m3 of average carrying capacity. In this case, the relationship between the hourly cost and the carrying capacity is 1,24 €/m3h. The following step, the transport to the bio-refinery, showed how the road train is the more economical solution with a cost of 1,24 €/m3h.

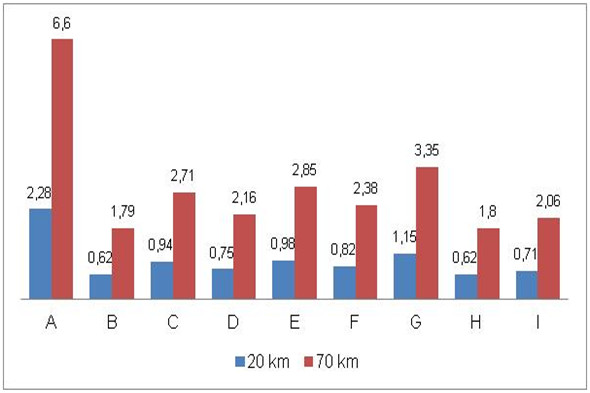

Both logistic sectors (agricultural and road transport) have registered a cost lower than one euro for distances up to a maximum of 20 km only (see figure below).

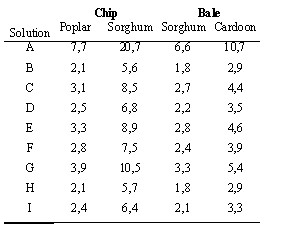

In in the following table are shown the transportation cost obtained according to the type of biomass and the transportation system used (distance between production point and transportation point equal to 20 km). It is simply deducible how a reduced weight per unit of volume determines a significant increase of transportation costs.

For higher distances there were registered significant cost increases for all types of biomass considered.

For higher distances there were registered significant cost increases for all types of biomass considered.

For all types of biomass, the transportation costs is unquestionably higher for distances exceeding 20 km, so the sustainability of cultivation might be compromised. Considering the case of dry bulk biomass, its handling has greatly influenced the transportation costs because of the low quantities of product handled.

For all types of biomass, the transportation costs is unquestionably higher for distances exceeding 20 km, so the sustainability of cultivation might be compromised. Considering the case of dry bulk biomass, its handling has greatly influenced the transportation costs because of the low quantities of product handled.

Hence, the chemical and physical properties of the material obtained have a pivotal role in addressing the choice of the most convenient machine to use.

The harvesting, the form, and the moisture content are very important aspects for the logistics of the agro-energy chain. Even the product obtained from the same crop is often different for moisture content and dimension according to the mechanization system used. For this reason, the intervention modalities are defined considering the end use of the product. In order to optimize the agro-energy chain it is fundamental to study the individual case adopting all precautions for reducing the transportation costs. It would be achievable reducing the distance between the areas of production and transformation.

The management of the bulk dry products has serious incidences on transportation costs because of the small quantity of product that can be moved. Increasing the distance until 20 km requires pressed material (density over 200 kg/m3). For transportation over 20 km, the costs progressively increase until compromising the convenience of the investment. Finally, the preparation of the harvesting modalities and the choose of the most suitable machine and transportation method represent fundamental aspects to be taken into account for guaranteeing a sufficient profitability of the crop.